On-Demand Manufacturing

With our vast experience in designing, developing, and delivering projects across various industries, we have built a global network of highly accurate, reliable manufacturering partners.

They enable us to provide rapid response, low-cost prototypes, and low to medium volume parts to your door.

P O W E R E D B Y

G L O B A L P A R T N E R S

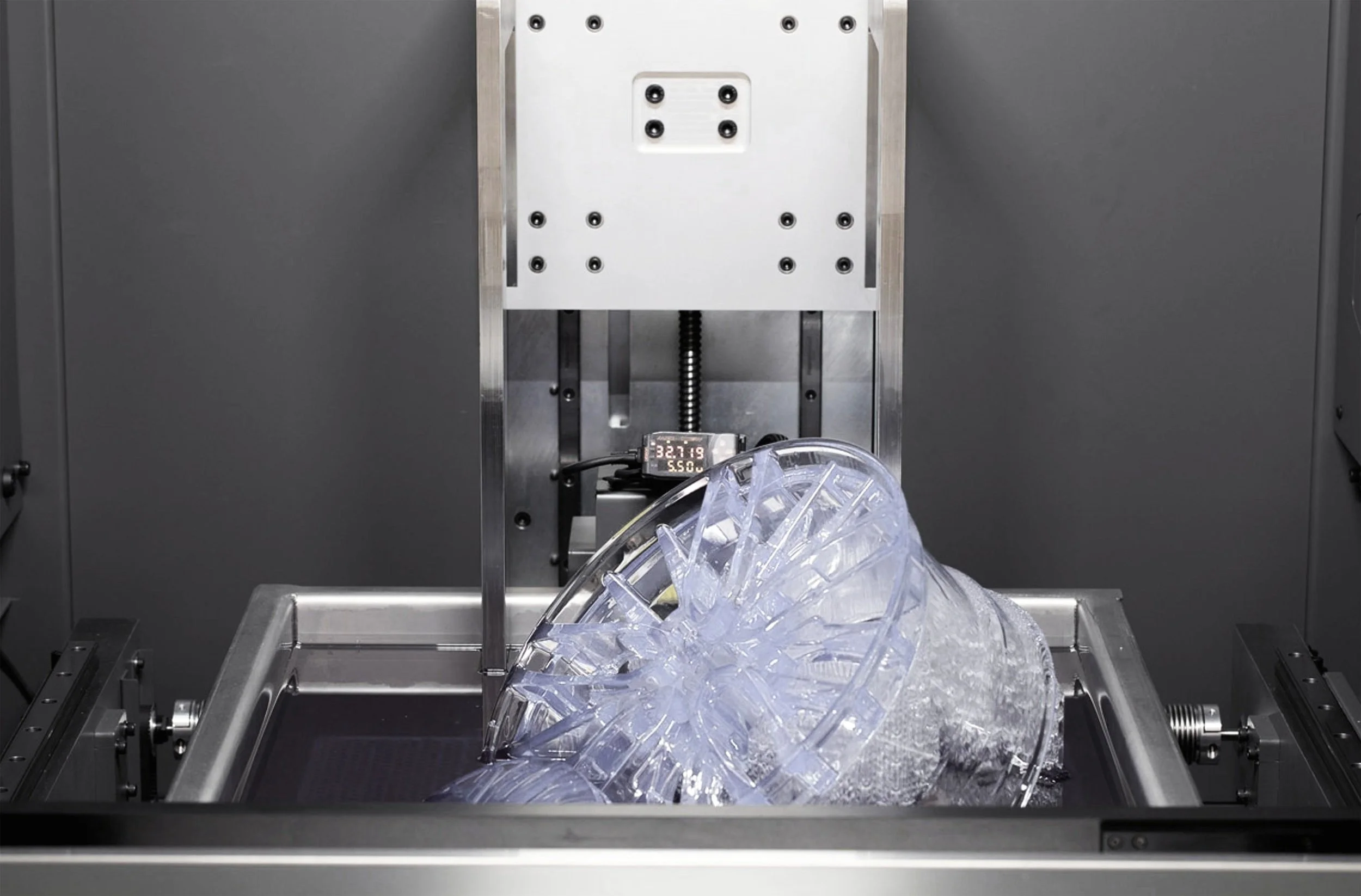

3 D P R I N T I N G

With our extensive network of state-of-the-art 3D printing facilities, we have earned a renowned reputation for producing exceptional prototypes and low volume components at competitive prices.

Our capabilities span from precise rapid prototyping using Fused Deposition Modelling (FDM) to the advanced manufacturing of functional end parts through techniques like Selective Laser Sintering (SLS) and Multi Jet Fusion (MJF).

We proudly provide a diverse selection of metal 3D printing services tailored to meet the specific needs of the Automotive, Marine, and Medical industries.

Our commitment to excellence consistently exceeds industry expectations, solidifying our prominent position in the field of 3D printing.

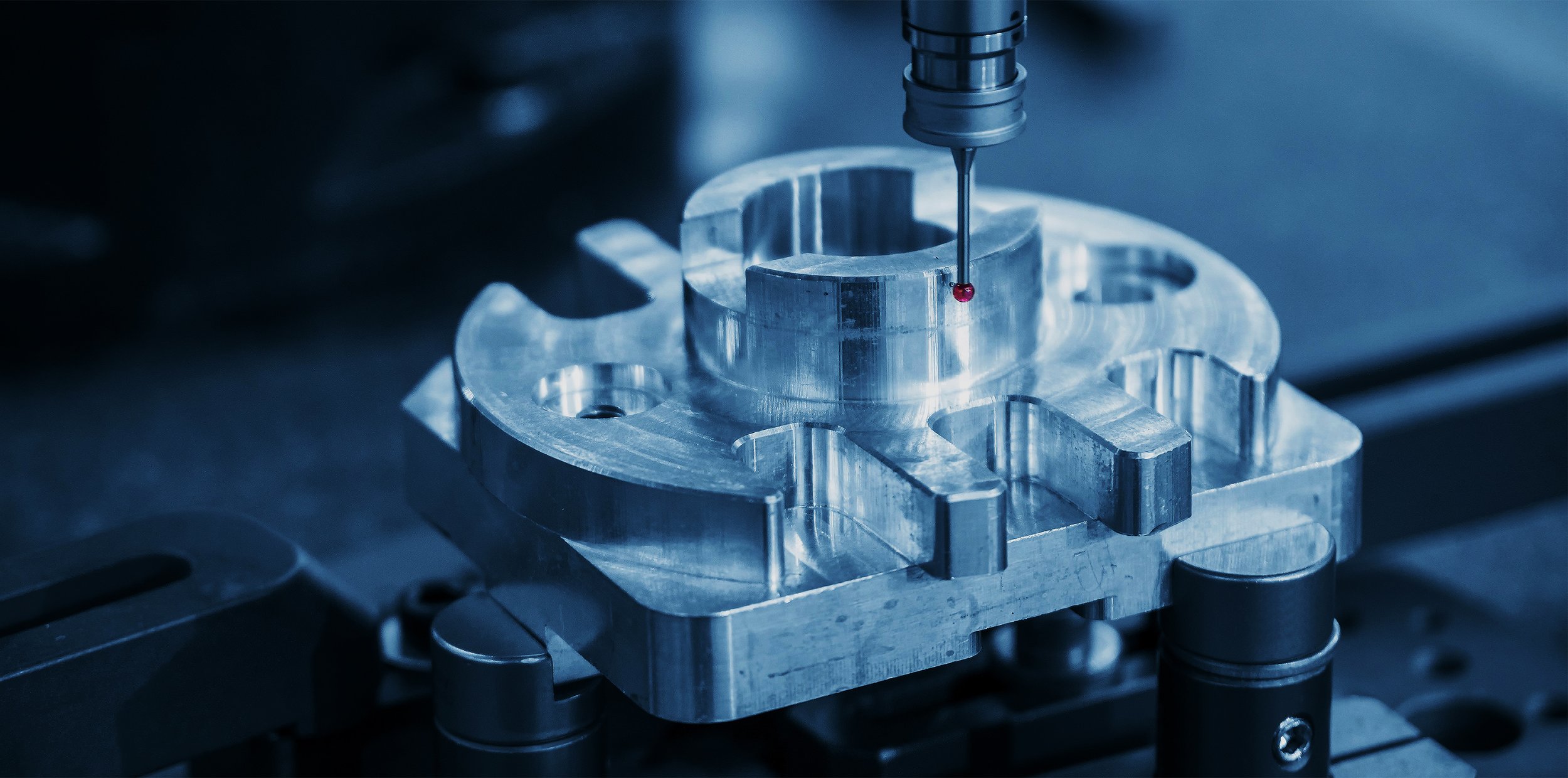

C N C M A C H I N I N G

Our CNC milling process is capable of producing custom prototypes and production parts within one day. We employ 3-axis milling and 5-axis indexed milling techniques to manufacture components from a selection of over 30 engineering-grade plastics and metals.

We have access to an extensive range of CNC mills and turning centre's that allow us to handle various machining needs. We pride ourselves on machining whatever you require. We can also utilise EDM and grinders when requested.

Ultimately, our goal is to provide a comprehensive machining service that caters to a wide range of customer needs. Whether you require simple work holdings or intricate parts with demanding specifications, we have the expertise, equipment, and dedication to deliver exceptional results.

C A R B O N F I B R E

Pure Studio Composites excels across a spectrum of applications, serving as an ideal choice for diverse manufacturing needs.

With advanced capabilities in Prototype Composites Manufacturing, it's tailored for demonstrative models and validating concepts. Its proficiency extends from small to medium volume and series production, ensuring efficient creation of composite structures.

Low to medium volume manufacturing thrives in motorsport, aftermarket, and high-end automotive sectors, accommodating regular design updates.

P L A S T I C S

Our custom injection moulding services cater to a wide range of part complexities and sizes, from 10 mm to 2.5 meters, serving industries such as automotive, electronics and consumer goods. Our experienced project engineers provide comprehensive assistance from rapid prototypes to production parts, ensuring a seamless order process.

We excel in versatility, using advanced equipment for projects ranging from small components to large ones such as car bumpers. We validate designs with advanced software, maintaining tight tolerances for precision injection moulding.

Our customer-centric approach ensures effective communication and collaboration, keeping clients informed from design to delivery. We strive to exceed expectations with reliable, high-quality solutions that drive business success.

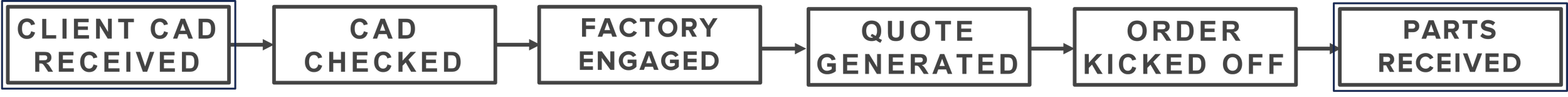

P R O J E C T A S S U R A N C E

Pure Studio provides you with the freedom to choose between local and international parts ordering options, guaranteeing impeccable quality standards regardless of your selection.

Local sourcing ensures prompt delivery, albeit at a slightly higher cost, while international sourcing offers a more cost-effective solution. Moreover, we assume full responsibility for the customs clearance expenses associated with internationally sourced orders, further simplifying the process.

At our core, we are dedicated to delivering unparalleled quality assurance in the industry. Our team comprises exceptionally talented engineers who examine your files and parts at every stage, starting from the initial quote all the way to the final inspection. By adopting this rigorous approach, we guarantee your utmost satisfaction with the results, ensuring that we get it right the first time, every time.